Measuring sound levels in straight pipe exhaust systems is key for performance and environmental assessment. Specialized equipment gauges decibel levels under various driving conditions, offering insights into noise-mitigating capabilities of different designs. Professionals use data to compare upgrades, adhering to regulations. Design factors like material, length, diameter, and heat management impact sound quality; optimization aims for quieter, refined driving experiences through advanced noise reduction techniques and features.

In the quest for quieter urban environments, understanding the acoustic properties of straight pipe exhaust systems is paramount. This article delves into the comparative analysis of sound levels across diverse designs, shedding light on the impact of structural variations. We explore practical methods for measuring noise and present an in-depth examination of various noise reduction techniques. By comparing straight pipe exhausts, we aim to equip readers with insights to optimize silence and contribute to more peaceful urban spaces.

- Measuring Sound Levels in Straight Pipe Exhausts

- Design Variations and Their Acoustic Impact

- Optimizing Silence: Comparing Noise Reduction Techniques

Measuring Sound Levels in Straight Pipe Exhausts

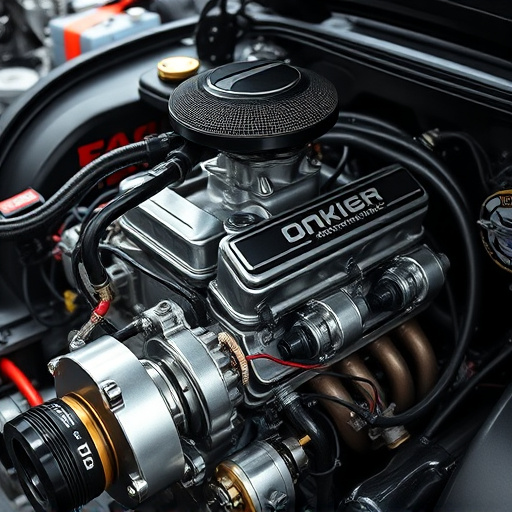

Measuring sound levels in straight pipe exhaust systems is a crucial aspect of understanding their performance and potential environmental impact. To accurately assess noise emission, specialized equipment is employed, including sound level meters designed for automotive applications. These devices measure the decibel (dB) levels produced by the exhaust system under various operating conditions, such as idle, acceleration, and cruising speeds. The data collected provides insights into the effectiveness of different straight pipe designs in mitigating noise pollution.

Professionals often utilize these measurements to compare the performance of alternative exhaust components like coilover kits, muffler tips, or full exhaust mufflers. By quantifying sound levels before and after modifications, they can determine the impact of each component on reducing noise levels, thereby guiding decisions for optimal exhaust system upgrades while adhering to local noise regulations.

Design Variations and Their Acoustic Impact

The design of a straight pipe exhaust system plays a significant role in its acoustic properties and overall sound output. Variations in construction and material choice can lead to notable differences in sound levels and the quality of noise produced. For instance, the use of different metallurgies like stainless steel or aluminum can affect resonance and vibration, resulting in distinct tonal characteristics. Additionally, the inclusion of performance air filters or suspension kits might alter the exhaust note due to changes in airflow dynamics.

Furthermore, the overall length and diameter of the pipes contribute to the sound’s propagation and intensity. Longer pipes tend to produce deeper tones, while shorter ones may result in a brighter, more aggressive sound. Brake components, too, can indirectly influence acoustics by affecting the system’s heat management and potential vibration levels. These design considerations are crucial when aiming to achieve desired performance and aesthetic outcomes in automotive customization.

Optimizing Silence: Comparing Noise Reduction Techniques

In the quest for quieter and more refined driving experiences, the focus on sound levels within straight pipe exhaust systems has become increasingly significant. Optimizing silence is an art, and various techniques are employed to reduce noise pollution from vehicles. One of the most effective methods involves integrating advanced noise reduction materials and designs into the exhaust system. By utilizing specialized acoustic insulations and meticulously crafted internal chambers, manufacturers can significantly dampen sound waves, transforming a rumbling engine into a harmonious melody.

When comparing straight pipe designs, it’s crucial to explore the impact of different noise reduction techniques. Some systems employ strategic placements of silencers, while others utilize innovative materials like glass wool or high-tech composite fibers. Additionally, incorporating features such as cold air intakes and suspension components (or suspension kits) can further enhance overall vehicle silence. These modifications contribute to a smoother, more refined driving experience, ensuring that the roar of the engine doesn’t overpower the passenger compartment.

In comparing sound levels across various straight pipe designs, this analysis highlights the significant impact of design variations on the acoustic performance of exhaust systems. By examining different techniques for noise reduction, we’ve identified promising methods for optimizing silence in straight pipe exhausts. These findings not only aid engineers in developing quieter and more environmentally friendly vehicle emissions but also offer consumers a clearer understanding of the acoustic characteristics they can expect from various exhaust designs.