Straight pipe exhaust systems offer significant advantages in automotive tuning by providing a smooth, unobstructed flow for exhaust gases, leading to faster combustion chamber warm-ups and enhanced engine response. These systems improve power output, torque, acceleration, and fuel efficiency, and can be paired with high-flow air filters and performance brakes for optimal performance. They address the restrictions of complex designs during cold starts, resulting in better overall vehicle control and efficiency.

In the realm of automotive engineering, understanding cold start behavior is crucial for optimal engine performance. This article explores how adopting a straight pipe exhaust system can significantly alter these initial operating conditions. While traditional exhaust designs present challenges during cold starts, straight pipes offer distinct advantages. We delve into the benefits of their simplified flow dynamics, examining their positive impact on engine warm-up and overall efficiency. By embracing this straightforward approach, vehicles can achieve smoother, more responsive startups.

- Understanding Cold Start Challenges in Exhaust Systems

- Advantages of Straight Pipe Design for Improved Performance

- Impact on Engine Warm-up and Efficiency During Cold Starts

Understanding Cold Start Challenges in Exhaust Systems

In the realm of automotive tuning, the exhaust system plays a pivotal role in enhancing engine performance, especially during the initial stages of operation—the cold start. Cold start challenges are multifaceted, stemming from various factors within the exhaust setup. One of the primary culprits is the complexity of gas flow dynamics in curved or convoluted pipes, which can hinder efficient combustion and fuel ignition. This is particularly noticeable in vehicles equipped with intricate exhaust systems designed for aesthetics over aerodynamics, including those with catbacks featuring bent pipes.

Substituting a standard setup with a straight pipe exhaust offers a simple yet effective solution. By eliminating curves and bends, these high-performance parts ensure smoother gas flow, enabling quicker warm-up of the combustion chamber during cold starts. This is particularly beneficial for vehicles with modified intake components designed to maximize airflow, as it ensures optimal synchronization between intake and exhaust systems. Moreover, straight pipe exhausts can complement performance brakes by providing a more responsive engine response, contributing to overall vehicle control and handling in demanding driving conditions.

Advantages of Straight Pipe Design for Improved Performance

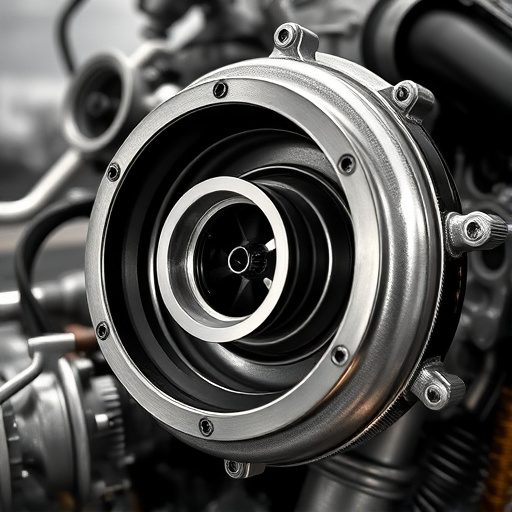

The design of a straight pipe exhaust system offers several advantages that contribute to improved vehicle performance. Unlike twisted or convoluted exhaust systems, which can create backpressure and limit engine efficiency, straight pipes provide a smooth, unobstructed path for exhaust gases to exit. This streamlined design allows for better airflow, enabling the engine to breathe more efficiently. As a result, engines experience enhanced power output and torque, leading to faster acceleration and improved overall performance.

Moreover, straight pipe exhaust systems can enhance fuel efficiency by reducing the energy lost through backpressure. This reduction in resistance allows the engine to operate more smoothly, optimizing fuel burning and potentially extending vehicle range. Additionally, these systems often include high-flow air filter kits for cleaner intake air, which further bolsters engine performance. Even the addition of performance brakes can complement a straight pipe exhaust, providing a balanced upgrade that enhances both engine output and control.

Impact on Engine Warm-up and Efficiency During Cold Starts

When it comes to cold start behavior, a straight pipe exhaust system can significantly impact engine performance and efficiency. During the initial startup phase, traditional exhaust systems often restrict airflow, leading to slower warm-up times. This is because curved or complex designs can cause turbulence, delaying the optimal flow of gases and cooling down the combustion chamber effectively. As a result, engines may struggle to reach their full power output immediately after starting.

However, straight pipe exhaust systems address these issues by promoting streamlined gas flow. The straightforward design allows for quicker warm-up, ensuring that the engine receives adequate oxygen supply right from the beginning. This efficiency is particularly noticeable in performance brakes and can lead to better overall performance. Additionally, a well-designed straight pipe system can enhance air filtration by integrating high-quality air filter kits, further optimizing the engine’s cold start experience.

In conclusion, adopting a straight pipe exhaust system offers significant advantages for improved engine performance during cold starts. By eliminating the complexities of bent pipes, this design streamlines gas flow, resulting in quicker warm-up times and enhanced efficiency. This simple yet effective modification is a game-changer for those seeking to optimize their vehicle’s cold start behavior, ensuring a smoother and more responsive driving experience.